1998

1998년에 저희 아버지는 중국 절강성 가싱에서 하드웨어 공장을 설립하셨습니다. 시작은 다양한 금속가공 하드웨어 부품을 생산하는 가족 공방이었습니다.

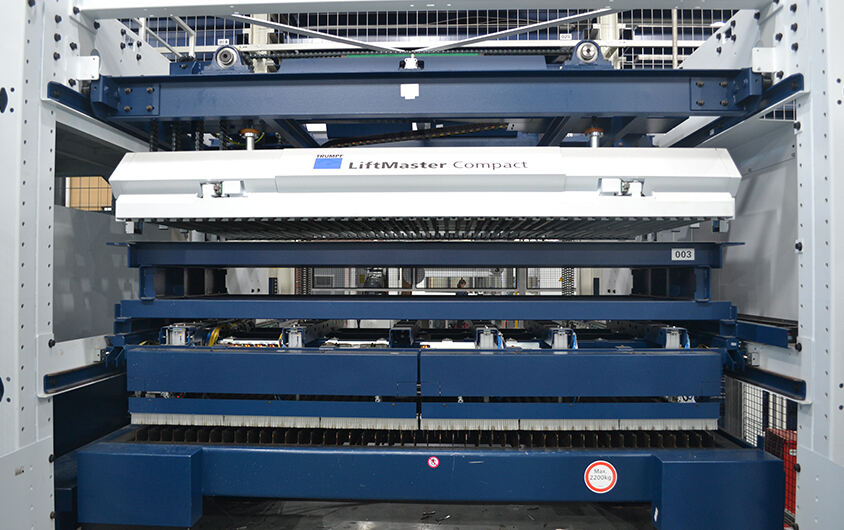

전통적인 금속 가공 공장과 달리, 우리는 독일의 TRUMPF 기술로 구동되는 완전 자동화된 시트 메탈 설비를 보유하고 있습니다. 개별 부품이든 전체 시트 메탈 전기 제어 캐비닛 세트가 필요하더라도, 우리는 귀하의 정확한 사양에 맞게 맞춤 제작할 수 있습니다. 우리의 시트 메탈 작업장은 레이저 절단, 펀칭, 벤딩 및 원자재에서 반제품으로 이동하는 과정을 자동화된 시스템으로 통합하여 높은 장비 활용율을 달성하며 24시간 무인 생산을 가능하게 하여 매번 적시 배송을 보장합니다. 우리는 무인 자동 저장 및 검색 시스템(AS/RS)을 사용하며, 이 지능형 시스템은 원자재를 절단, 펀칭 및 벤딩 공정을 통해 반제품으로 자동 라우팅하여 회전 효율성을 크게 향상시키고 낭비를 최소화합니다. 우리가 일반적으로 다루는 시트 메탈 부품에는 케이스, 브래킷, 조립체 및 완전한 전기 제어 캐비닛 세트가 포함됩니다.

1998년에 저희 아버지는 중국 절강성 가싱에서 하드웨어 공장을 설립하셨습니다. 시작은 다양한 금속가공 하드웨어 부품을 생산하는 가족 공방이었습니다.

2010년에 저희 아버지는 은퇴하셨습니다. 저는 대학을 졸업하고 전통적인 제조업과 디지털 스마트 기능을 결합한 현대적인 공장을 설립하려는 꿈을 안고 있었습니다. 하지만 어떻게 이를 달성할지는 확실하지 않았고, 단순히 생계를 유지하려는 목표로 시작했습니다. 저는 사무실을 임대하여 첫 번째 무역 회사인 Zhejiang Jiahui Wire & Cable Co., Ltd.를 설립하며 창업의 길에 들어섰습니다.

2015년에 우리는 사업을 전기 제품의 다양한 카테고리로 확장하기 위해 JiaHui Electric co., ltd.를 설립했습니다.

자동차, 센서, 중공업, 광산, 트레일러, 전자제품, 건물 케이블 등에 대한 맞춤형 솔루션을 제공하는 Jiahui 케이블 공장을 시작했습니다.

우리는 전기 공장을 인수하고 맞춤형 전력 배전함 산업으로 진출했습니다.

2023년에 우리는 Siemens, SAP, PDM, MX, NS와 같은 회사들과 협력하여 와이어 및 케이블, 전기 부품, 배전함, 금속 가공, 금형 제조 및 자동화 부서라는 핵심 비즈니스 기반으로 전체 체인 디지털 드라이브 관리 시스템을 개발했습니다. 이 시스템은 우리의 다섯 부서를 연결하여 고객과 공급업체 간의 실시간 정보 공유 및 상호 작용을 가능하게 하고, 데이터 전송의 불일치, 제조 노드의 사각 지대, 이산적이고 유연하며 맞춤형 공장에서의 비효율적인 의사소통 문제를 해결합니다.

2024년에 스마트 3차원 창고, AGV 물류 시스템, 그리고 IoT 장치 상호 연결을 통합함에 따라 우리 디지털 스마트 팩토리의 프로토타입이 등장했습니다. '디지털 지능형 제조 및 공예계승'이라는 개념을 바탕으로 더 많은 산업에 산업용 맞춤형 서비스를 제공하기를 목표로 합니다.

R&D 디자이너

빠른 프루핑(시간)

생산 지역

온라인 서비스(시간)