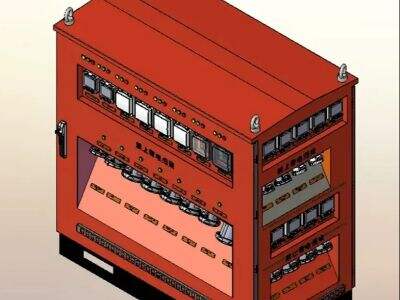

Custom boxes made of sheet metal: Special rules applied. These rules are called quality standards Because becoming them is really review importantIy to helps meet we have to the boxes well made and function. Here at JHW, we know how important it is to follow these specifications of quality. We believe that this commitment is what makes our distribution boxes the best they can be.

Good practices are well established standards that help us show the boxes in a process. We can ensure that the boxes we create are strong, safe and perform as expected by not skipping any of these steps. Translation translates into the fact that when someone uses our boxes, they know they will work and do what they are supposed to do.

Beyond quality standards, we also need to abide by regulations which all companies need to comply with during the manufacturing of their goods. These rules are what we call industry regulations. They are designed to protect consumers and make sure products are safe and no dubious. Adhering to these guidelines helps us ensure that our boxes are both safe and industry compliant.

Being careful and precise is another important part of making distribution boxes. Precision and accuracy is making sure we take our time with that box to ensure eery section of the box fits like a glove. When we are clear, we limit the potential for errors, and we can make sure that the boxes are quality, as they are meant to be. All this attention to detail ensures that our boxes, and accessories, are the best they can be.

Materials Selection One other essential step is choosing the correct materials for our boxes. Selecting robust & durable materials means our boxes are going to be long-lasting. It’s not only about prettifying the boxes; they also have to be able to stand up to the weight and pressure they could eventually have to bear. The methods we use to make our boxes is just as important. Basic responsiveness to manufacturing allows us to design boxes that pack a punch, and can be relied on to perform their job for our customers.

As well as that, ongoing quality control and these types of measures are also both part of our process. Quality control is a set of checks we do to ensure that processes are being followed accordingly. If we repeatedly check, we end up making our boxes right, and all the quality parameters we set also match. It's an ongoing process that helps ensure the integrity of our boxes so that they function correctly and are in great shape.

Quality standards are very important for a variety of reasons when producing custom sheet metal distribution boxes. Quality Control in Bending and Forming Accurate Bending Forming Packaging Box We manufacture the highest quality sheet metal distribution boxes, customized to meet the needs of your application, at JHW and pride ourselves on having the absolute highest quality work products available. And we want to provide our customers what they need and we want to make boxes our customers can lean on.