Our factory is an advanced manufacturing enterprise specializing in high-precision sheet metal processing. Leveraging fully automated production lines and cutting-edge technical support, we provide high-quality sheet metal components and related services across various industries. Strategically located in Ningbo, a highly developed coastal city in China, our factory spans an area of 40,000 square meters, possesses state-of-the-art equipment and an experienced technical team.

Production Capacity

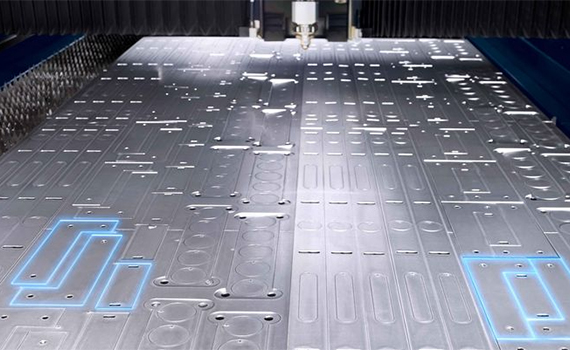

We have introduced internationally advanced automation equipment to provide strong support for our sheet metal processing, encompassing automatic bending machines, laser cutting machines, automatic punching machines, welding machines, and automated eco-friendly spray plating lines. Additionally, our factory is equipped with intelligent logistics systems that run through the entire sheet metal manufacturing process, from raw material to final products.

Our production lines incorporate the latest precision measurement instruments and control systems, enabling monitoring and adjustment at the 0.1mm level. Post-cutting and punching products are burr-free, with each piece undergoing rigorous quality inspections to ensure compliance with customers' precise specifications and requirements.

Automation is a defining characteristic of our production capabilities. From design, programming, production to inspection, our entire process is highly integrated, leveraging IoT technology and big data analytics for real-time monitoring and optimization. This automation not only enhances production efficiency but also significantly reduces the potential for human error, ensuring continuous and stable operation of our production lines.

We are committed to environmentally friendly production, implementing a series of eco-friendly measures including energy recovery systems, wastewater treatment systems, and high-efficiency adsorption equipment. By optimizing resource allocation and promoting circular utilization of emissions, our factory has achieved remarkable results in reducing its carbon footprint.

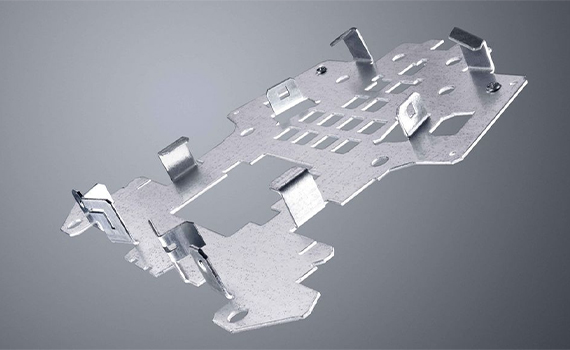

Beyond standard sheet metal processing services, we offer a diverse range of value-added services, including mold development, product design, surface treatment, electrical accessory design and manufacturing, and distribution box assembly. Our engineering team, with extensive experience, can tailor customized solutions to meet our clients' needs, ensuring that every product exceeds their expectations.

Our customer base spans diverse industries, including electronics, medical devices, mineral exploration, energy storage and photovoltaics, national power maintenance, shipbuilding, subway projects, and early-stage infrastructure development. With our exceptional product quality and reliable supply capabilities, we have forged long-term partnerships with numerous global enterprises.

| Material | Thickness min.~max.(mm) | Material | Thickness min.~max.(mm) |

| Iron | 0.5~25 | Tisco | 0.5~10 |

| Stainless Streel | 0.5~25 | Copper | 0.5~10 |

| Aluminum | 0.5~25 | Brass | 0.5~10 |

One punchcan complete all the processing steps including puching, splitting, forming, processing countersunk holes, tapping, rolling, marking and deburring. To abtain high quality precision geometry that produces no piercings or splatters and no ripples or scratches. Moreover, it saves time because the equipment and programming work only needs to happen once.

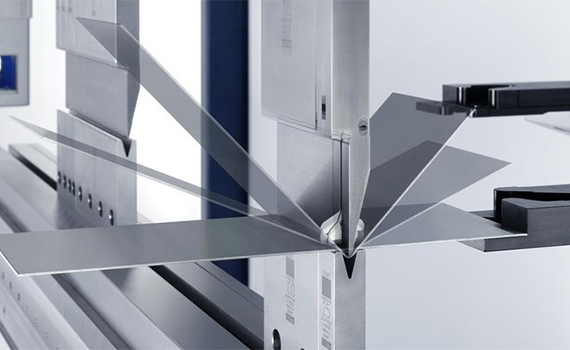

With the new ACB Speed, you only need to measure the rebound on the first bend. The software then intelligently applies the evaluated data to all the other parts-saving you up to 35% in cycle time.